Chemical Applications

Providing an essential role in hydrocarbon processing applications from fired heaters to steam reformers, used in syngas production, to subsequent refining processes for the production of fertilisers for essential nutrients that feed our plants and crops to pharmaceutical equipment operating under cryogenic conditions.

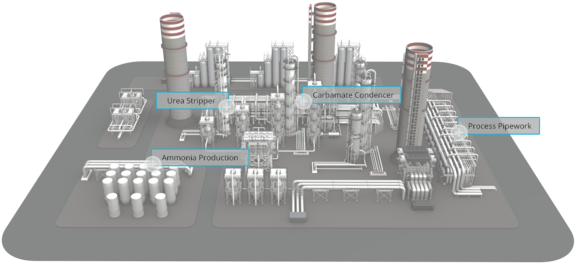

From providing the essential nutrients for the growth of our plants and crops to dermataological skin products to the whitening of our smile the fertilizer industry and associated key processes of UREA and ammonia production are an essential ingredient in today’s lives.

Fertilizer production processes present environments with aggressive corrosion conditions, such as with Ammonium carbamate production at 180 ºC (356 ºF) to 250 ºC (482 ºF) and 150 bar (15 MPa).

With associated processes such as nitric acid, sulphuric acid, phosphoric acid and melamine production more sophisticated solutions to the use of conventional stainless grades such as 304L/316L are required.

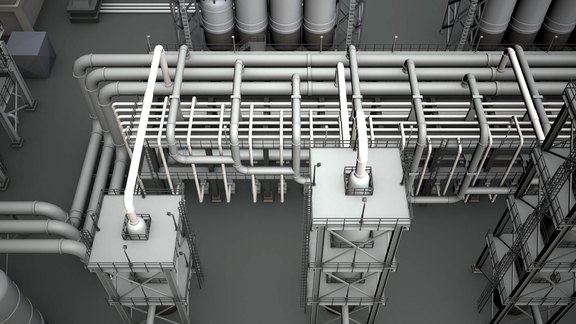

From condensers to cooling towers consideration must be given to the differing types of corrosion presented by the potentially aggressive chemical plant corrosive environments.

Austenitic

| MST designation | Attribute | Nearest equivalent standard | Typical chemical composition 1) | Density | Min. mechanical prop. at RT | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| UNS | EN | JIS | Cmax | Cr | Ni | Mo | Cu | others | Rp0.2 Yield Strength | Rm Tensile Strength | ||||||

| g/cm3 | lb/in3 | MPa | ksi | MPa | ksi | |||||||||||

| DMV 304 | Corrosion Resistant | S30400 | 1.4301 | SUS 304 | 0.06 | 18.5 | 9.5 | 7.9 | 0.29 | 205 | 30 | 515 | 75 | |||

| DMV 304L | Corrosion Resistant | S30403 | 1.4306 | SUS 304L | 0.03 | 19.0 | 11.0 | 7.9 | 0.29 | 170 | 25 | 485 | 70 | |||

| DMV 304LN | Corrosion Resistant | S30453 | 1.4311 | 0.03 | 18.0 | 10.0 | 7.9 | 0.29 | 205 | 30 | 515 | 75 | ||||

| DMV 321 | Corrosion Resistant | S32100 | 1.4541 | SUS 321 | 0.08 | 18.5 | 10.5 | 5 x C < Ti < 0.6 | 7.9 | 0.29 | 170 | 25 | 485 | 70 | ||

| DMV 347 | Corrosion Resistant | S34700 | 1.4550 | SUS 347 | 0.08 | 18.5 | 11.0 | 10 x C < Nb < 1.0 | 7.9 | 0.29 | 205 | 30 | 515 | 75 | ||

| DMV 316 | Corrosion Resistant | S31600 | 1.4401 | SUS 316 | 0.06 | 17.0 | 11.5 | 2.25 | 8.0 | 0.29 | 205 | 30 | 515 | 75 | ||

| DMV 316L | Corrosion Resistant | S31603 | 1.4404 | 0.03 | 17.0 | 12.0 | 2.25 | 8.0 | 0.29 | 170 | 25 | 485 | 70 | |||

| DMV 316LMoS | Corrosion Resistant | S31603 | 1.4435 | SUS 316L | 0.03 | 17.0 | 12.5 | 2.75 | 8.0 | 0.29 | 170 | 25 | 485 | 70 | ||

| DMV 316LN | Corrosion Resistant | S31653 | 1.4429 | 0.03 | 17.0 | 12.5 | 2.75 | 0.12 < N < 0.22 | 8.0 | 0.29 | 205 | 30 | 515 | 75 | ||

| DMV 316Ti | Corrosion Resistant | S31635 | 1.4571 | 0.08 | 17.0 | 11.5 | 2.25 | 8.0 | 0.29 | 205 | 30 | 515 | 75 | |||

| DMV 316LVM | Corrosion Resistant | S31673 | 1.4441 | 0.025 | 17.5 | 14.0 | 2.8 | <0.10 | N<0.10 | 8.0 | 0.29 | 190 | 28 | 490 | 71 | |

| DMV 317L | Corrosion Resistant | S31703 | 1.4438 | SUS 317L | 0.03 | 18.0 | 14.5 | 3.5 | 8.0 | 0.29 | 205 | 30 | 515 | 75 | ||

| DMV 316LUG | Corrosion Resistant | S31603 | 1.4435 | 0.02 | 17.0 | 13.5 | 4.5 | 8.0 | 0.29 | 170 | 25 | 485 | 70 | |||

| DMV 309 | Corrosion Resistant | S30900 | 1.4828 | SUS 309 TB | 0.07 | 25.0 | 14.0 | 7.9 | 0.29 | 205 | 30 | 515 | 75 | |||

| DMV 306Si | Corrosion Resistant | S30600 | 1.4361 | 0.015 | 18.0 | 15.0 | Si 4 | 7.9 | 0.29 | 240 | 35 | 540 | 78 | |||

| DMV 4439 | Corrosion Resistant | (S31726) | 1.4439 | 0.03 | 17.5 | 13.5 | 4.5 | N 0.16 | 8.0 | 0.29 | 240 | 35 | 550 | 80 | ||

| DMV 4335 | Corrosion Resistant | S31002 | 1.4335 | 0.015 | 25.0 | 20.5 | N<0.10 | 7.9 | 0.29 | 255 | 37 | 540 | 78 | |||

| DMV 25.22.2 | Corrosion Resistant | S31050 | 1.4466 | 0.02 | 25.0 | 22.0 | 2.0 | N 0.12 | 7.9 | 0.29 | 255 | 37 | 540 | 78 | ||

| DMV 310S | Corrosion Resistant | S31008 | 1.4845 | 0.015 | 25.0 | 21.0 | 7.9 | 0.29 | 205 | 30 | 515 | 75 | ||||

| DMV 904 | Corrosion Resistant | N08904 | 1.4539 | 0.02 | 20.5 | 25.5 | 4.5 | 1.5 | 8.0 | 0.29 | 215 | 31 | 490 | 71 | ||

| DMV 926 | Corrosion Resistant | N08926 | 1.4529 | 0.02 | 20.0 | 25.0 | 6.5 | 0.8 | N 0.20 | 8.0 | 0.29 | 295 | 43 | 650 | 94 | |

| DMV 954 | Corrosion Resistant | S31254 | 1.4547 | 0.02 | 20.0 | 18.0 | 6.2 | N 0.20 | 8.0 | 0.29 | 310 | 45 | 655 | 95 | ||

| DMV 304H | Heat Resistant | S30409 | 1.4948 | 0.08 2) | 18.5 | 9.5 | 7.9 | 0.29 | 205 | 30 | 515 | 75 | ||||

| DMV 304HCu | Heat Resistant | 1.4907 | 0.13 2) | 18.5 | 9.5 | 3.0 | N 0.10; Nb 0.5 | 7.9 | 0.29 | 235 | 34 | 590 | 85 | |||

| DMV 321H | Heat Resistant | S32109 | 1.4940 | 0.08 2) | 18.5 | 11.0 | Ti > 4 x C < 0.6 | 7.9 | 0.29 | 170 | 25 | 480 | 70 | |||

| DMV 347H | Heat Resistant | S34709 | 1.4912 | 0.08 2) | 18.5 | 11.0 | Nb > 8 x C < 1.0 | 7.9 | 0.29 | 205 | 30 | 515 | 75 | |||

| DMV 347HFG | Heat Resistant | 1.4908 | 0.10 2) | 18.5 | 11.0 | Ti+Nb > 8xC < 1.0 | 7.9 | 0.29 | 205 | 30 | 550 | 80 | ||||

| DMV 310H | Heat Resistant | S31009 | 1.4845 | SUS 310 TB | 0.10 2) | 25.0 | 20.0 | 8.0 | 0.29 | 205 | 30 | 515 | 75 | |||

| DMV 310N | Heat Resistant | S31042 | 1.4952 | 0.10 2) | 25.0 | 20.0 | N 0.20; Nb 0.40 | 8.0 | 0.29 | 295 | 43 | 655 | 95 | |||

| DMV 4841 | Heat Resistant | 1.4841 | 0.10 | 25.0 | 20.5 | Si 2.0 | 8.0 | 0.29 | 205 | 30 | 515 | 75 | ||||

1) All figures in weight percentage. In case of order, the limits of the order specification will apply.

2) Minimum level of carbon content is mandatory.

Austenitic Ferritic

| MST designation | Nearest equivalent standard | Typical chemical composition 1) | Density | Min. mechanical prop. at RT | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| UNS | EN | Cmax | Cr | Ni | Mo | Cu | others | Rp0.2 Yield Strength | Rm Tensile Strength | |||||

| g/cm3 | lb/in3 | MPa | ksi | MPa | ksi | |||||||||

| DMV 22.5 | S31803 | 1.4462 | 0.03 | 22.0 | 5.5 | 3.0 | N 0.17 2) | 7.8 | 0.28 | 450 | 65 | 620 | 90 | |

| DMV 25.7N | S32760 | 1.4501 | 0.03 | 25.0 | 7.0 | 4.0 | 0.5 | N 0.25; W 0.5 2) | 7.8 | 0.28 | 550 | 80 | 750 | 109 |

| DMV 29.7 | S32906 | 1.4477 | 0.03 | 29.0 | 7.0 | 2.3 | < 0.80 | N 0.35 2) | 7.8 | 0.28 | 650 | 94 | 800 | 116 |

1) All figures in weight percentage. In case of order, the limits of the order specification will apply.

2) Min PRE value controlled.

Nickel and Nickel Based Alloys

| MST designation | Attribute | Nearest equivalent standard | Typical chemical composition 1) | Density | Min. mechanical prop. at RT | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| UNS | EN | Cmax | Cr | Ni | Mo | Cu | others | Rp0.2 Yield Strength | Rm Tensile Strength | ||||||

| g/cm3 | lb/in3 | MPa | ksi | MPa | ksi | ||||||||||

| DMV 200 | Pure Nickel | N02200 | 2.4066 | 0.05 | 99.4 | 8.9 | 0.32 | 103 | 15 | 379 | 55 | ||||

| DMV 201 | Pure Nickel | N02201 | 2.4068 | 0.02 | 99.4 | 8.9 | 0.32 | 83 | 12 | 345 | 50 | ||||

| DMV 400 | Nickel-Copper | N04400 | 2.4360 | 0.15 | 65.0 | 30.0 | Fe 2; Mn 1.5 | 8.8 | 0.32 | 180 | 26 | 450 | 65 | ||

| DMV 8020 | Corrosion Resistant | N08020 | 2.4660 | 0.02 | 20.0 | 34.0 | 2.5 | 3.5 | Nb + Ta | 8.1 | 0.29 | 240 | 35 | 550 | 80 |

| DMV 928 | Corrosion Resistant | N08028 | 1.4563 | 0.02 | 27.0 | 31.0 | 3.5 | 1.2 | N 0.10 | 8.0 | 0.29 | 210 | 31 | 500 | 73 |

| DMV 931 | Corrosion Resistant | N08031 | 1.4562 | 0.015 | 27.0 | 31.0 | 6.5 | 1.2 | N 0.20 | 8.1 | 0.29 | 280 | 41 | 650 | 94 |

| DMV 4692 | Corrosion Resistant | N08034 | 2.4692 | 0.01 | 27.0 | 35.0 | 6.5 | 1.5 | N 0.20 | 8.1 | 0.29 | 310 | 45 | 750 | 108 |

| DMV 800L | Corrosion Resistant | (N08800) | 1.4558 | 0.025 | 21.0 | 32.0 | Ti 0.30; Al 0.30 | 8.0 | 0.29 | 180 | 26 | 450 | 65 | ||

| DMV 800 | Corrosion Resistant | N08800 | 1.4876 | 0.08 | 21.0 | 32.0 | Ti < 0.40 | 8.0 | 0.29 | 210 | 31 | 500 | 73 | ||

| DMV 825 | Corrosion Resistant | N08825 | 2.4858 | 0.03 | 22.0 | 42.0 | 3.0 | 2.0 | Ti 0.80; Al 0.10 | 8.1 | 0.29 | 180 | 26 | 530 | 75 |

| DMV 600L | Corrosion Resistant | N06600 | 2.4817 | 0.025 | 16.0 | 76.0 | Fe 8 | 8.4 | 0.30 | 180 | 26 | 550 | 80 | ||

| DMV 690 | Corrosion Resistant | N06690 | 2.4642 | 0.02 | 29.0 | 60.0 | Fe 9 | 8.2 | 0.29 | 205 | 30 | 585 | 85 | ||

| DMV 625 | Corrosion Resistant | N06625 Gr.1 | 2.4856 | 0.025 | 22.0 | 63.0 | 9.0 | Nb 3.5 | 8.5 | 0.31 | 414 | 60 | 827 | 120 | |

| DMV G3 | Corrosion Resistant | N06985 | 2.4619 | 0.015 | 22.0 | 48.0 | 7.0 | 2.0 | Co;W | 8.3 | 0.30 | 205 | 30 | 585 | 85 |

| DMV C22 | Corrosion Resistant | N06022 | 2.4602 | 0.01 | 22.0 | 57.0 | 13.0 | W | 8.7 | 0.31 | 310 | 45 | 690 | 100 | |

| DMV 59 | Corrosion Resistant | N06059 | 2.4605 | 0.01 | 23.0 | 59.0 | 16.0 | Al | 8.6 | 0.31 | 340 | 50 | 690 | 100 | |

| DMV C4 | Corrosion Resistant | N06455 | 2.4610 | 0.01 | 16.0 | 66.0 | 16.0 | Ti | 8.6 | 0.31 | 280 | 41 | 700 | 102 | |

| DMV C276 | Corrosion Resistant | N10276 | 2.4819 | 0.01 | 16.0 | 57.0 | 16.0 | W | 8.4 | 0.30 | 350 | 51 | 750 | 109 | |

| DMV 800H | Heat Resistant | N08810 | 1.4958 | 0.10 2) | 21.0 | 32.0 | (Al.Ti) 0.15 - 0.60 | 8.0 | 0.29 | 170 | 25 | 500 | 73 | ||

| DMV 811 | Heat Resistant | N08811 | 1.4959 | 0.10 2) | 21.0 | 32.0 | 0.85 < Ti + Al < 1.20 | 8.0 | 0.29 | 170 | 25 | 500 | 73 | ||

| DMV AC66 | Heat Resistant | S33224 | 1.4877 | 0.06 | 27.0 | 32.0 | Ce 0.07; Nb 0.8 | 8.0 | 0.29 | 185 | 27 | 500 | 73 | ||

| DMV 600H | Heat Resistant | N06600 | 2.4816 | 0.07 | 16.0 | 76.0 | Fe 8 | 8.4 | 0.30 | 240 | 35 | 550 | 80 | ||

| DMV 625 | Heat Resistant | N06625 Gr.2 | 2.4856 | 0.025 | 22.0 | 63.0 | 9.0 | Nb 3.5 | 8.4 | 0.30 | 276 | 40 | 690 | 100 | |

| DMV 601 | Heat Resistant | N06601 | 2.4851 | 0.08 | 23.0 | 62.0 | Al 1.2; Ti 0.3 | 8.1 | 0.29 | 240 | 35 | 600 | 87 | ||

| DMV 617 | Heat Resistant | N06617 | 2.4663 | 0.08 | 22.0 | 55.0 | 9.0 | Co 12; Al; Ti | 8.4 | 0.30 | 300 | 44 | 700 | 102 | |

| DMV C263 | Heat Resistant | N07263 | 2.4650 | 0.08 | 20.0 | 52.0 | 5.8 | Co 20;Ti 2.1,Al 0.5;Mn <0.6 | 8.4 | 0.3 | 585 | 118 | 1004 | 145 | |

| DMV 718 | Corrosion Resistant | N07718 | 2.4668 | 0.08 | 19.0 | 52.5 | 3.0 | Nb 5.1;Mn 0.35;Ti 0.8;Al 0.5 | 8.2 | 0.29 | 1035 | 150 | 1276 | 185 | |

1) All figures in weight percentage. In case of order, the limits of the order specification will apply.

2) Minimum level of carbon content is mandatory.

Serving Applications Such As:

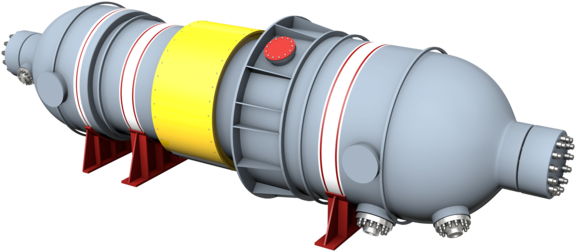

Urea strippers

Carbamate condensers

Tubes: U bent or straight tubes up to 43 m (110 ft) long.

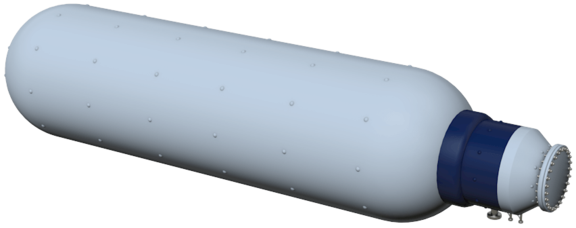

Bimetallic Tubes

Bimetallic tubes were developed as a solution to service some of the most aggressive environments associated with Urea strippers.

Consisting of an external tube of DMV 25.22.2 and internal tube lining of Zirconium grade 702 we innovated our process technology to ensure the integral bonding during the cold working process.

Bimetallic pipes and process pipework in typical dimensions up to 31 mm (1.22”) OD.