Nuclear Standards, Nuclear Pedigree

Our quality system accreditations and extensive customer references demonstrate our proven capabilities across the global nuclear industry.

From the control of our raw materials to final inspection, certification and shipment we apply the highest standards of product integrity, process control combined with the Mannesmann reassurance of product originality.

From our historical development of PWR power generation for the French (RCC-M) and US (ASME III) programs our knowledge and skills have developed across the global technologies: CANDU, VVER Rosatom, China CPR’s and India PHWR’s.

Applying our skills to the latest generation of EPR power plants whilst partnering with developing technologies and sciences such as CERN, ITER, small modular reactors, and marine vessels.

For over 50 years we have partnered with our global customers supplying stainless steel and nickel alloys tubes to the most exacting specification requirements.

Project Management:

Our nuclear experience reflects not only the exacting product requirements but also that of managing nuclear projects and providing all of the associated documentation requirements.

ASME Quality System Certificates

Our nuclear quality system approvals reflect our experience and commitment to global nuclear technologies.

✔️ ASME III certified

✔️ HAF 604- NNSA certified

✔️ RCC-M compliant

✔️ Label Fournisseur AREVA (Framatome)

✔️ ISO 19443

✔️ Extensive customer and design code accreditations

Nuclear Power Grades

| MST designation | Nearest equivalent standard | Typical chemical composition 1) | Density | Min. mechanical prop. at RT | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| UNS | EN | Cmax | Cr | Ni | Mo | Cu | others | Rp0.2 Yield Strength | Rm Tensile Strength | |||||

| g/cm3 | lb/in3 | MPa | ksi | MPa | ksi | |||||||||

| DMV 304L | S30403 | 1.4306 | 0.03 | 19.0 | 11.0 | 7.9 | 0.29 | 170 | 25 | 485 | 70 | |||

| DMV 4335 | S31002 | 1.4335 | 0.015 | 25.0 | 20.5 | N <0.10 | 7.9 | 0.29 | 255 | 37 | 540 | 78 | ||

| DMV 321 | S32100 | 1.4541 | 0.08 | 18.5 | 10.5 | 5 x C < Ti < 0.6 | 7.9 | 0.29 | 170 | 25 | 485 | 70 | ||

| DMV 316L | S31603 | 1.4404 | 0.03 | 17.0 | 12.0 | 2.25 | 8.0 | 0.29 | 170 | 25 | 485 | 70 | ||

| DMV 316LN | S31653 | 1.4429 | 0.03 | 17.0 | 12.5 | 2.75 | 0.12 < N < 0.22 | 8.0 | 0.29 | 205 | 30 | 515 | 75 | |

| DMV 800 | N08800 | 1.4876 | 0.08 | 21.0 | 32.0 | Ti < 0.40 | 8.0 | 0.29 | 210 | 31 | 500 | 73 | ||

| DMV 600L | N06600 | 2.4817 | 0.025 | 16.0 | 76.0 | Fe 8 | 8.4 | 0.30 | 180 | 26 | 550 | 80 | ||

| DMV 690 | N06690 | 2.4642 | 0.02 | 29.0 | 60.0 | Fe 9 | 8.2 | 0.29 | 205 | 30 | 585 | 85 | ||

| DMV 400 | N04400 | 2.4360 | 0.15 | 65.0 | 30.0 | Fe 2; Mn 1.5 | 8.8 | 0.32 | 180 | 26 | 450 | 65 | ||

| DMV 25.7N | S32760 | 1.4501 | 0.03 | 25.0 | 7.0 | 4.0 | 0.5 | N 0.25; W 0.5 | 7.8 | 0.28 | 550 | 80 | 750 | 109 |

| DMV 25.7NS | S32750 | 1.4410 | 0.03 | 25.5 | 7.0 | 4.0 | 0.25 | N 0.3 2) | 7.8 | 0.28 | 550 | 80 | 750 | 109 |

1) All figures in weight percentage. In case of order, the limits of the order specification will apply.

2) Min PRE value controlled

Class 1 Instrumentation Tubes

Class 1, 2 & 3 Instrumentation tubes according to RCC-M, ASME III, CSA N285 and HAF 604 standards.

| PRODUCT: TUBES | ||

|---|---|---|

| OD range | mm | Inch |

| min | 6.0 | 0.236 |

| max | 25.0 | 0.984 |

| WT range | mm | Inch |

| min | 0.5 | 0.02 |

| max | 2.5 | 0.098 |

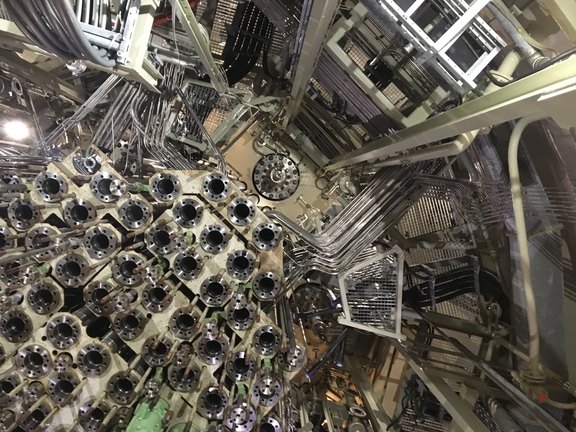

In-Core Measurement And Control

For in-core neutron flux distribution & temperature monitoring and as guide thimble tubes within rod cluster control assemblies. With tube diameters from 1.6 mm diameter in straight or coils forms with stainless and nickel alloys melted and refined to nuclear requirements.

| PRODUCT: TUBES | ||

|---|---|---|

| OD range | mm | Inch |

| min | 1.6 | 0.063 |

| max | 88.9 | 3.5 |

| WT range | mm | Inch |

| min | 0.5 | 0.02 |

| max | 25.0 | 0.984 |

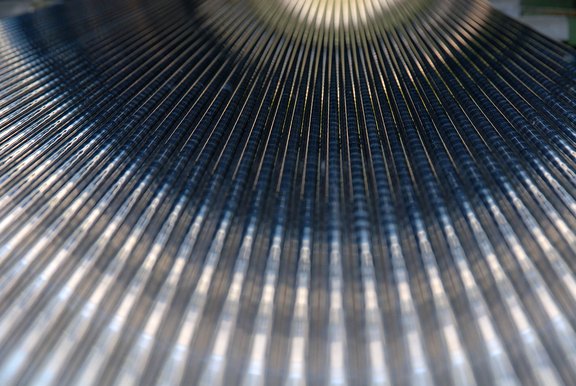

Heat Exchanger

Our heat exchanger tubes are used for critical components within the nuclear island, typically in the secondary circuit (class 2). We supply in straight lengths of U tube form. We work in close partnership with fabricators and designers.

| PRODUCT: U-BENT TUBES (up to 43 m / 141 ft long) | ||

|---|---|---|

| OD range | mm | Inch |

| min | 12.7 | 0.5 |

| max | 38.1 | 1.5 |

| WT range | mm | Inch |

| min | 0.89 | 0.035 |

| max | 4.5 | 0.177 |

| PRODUCT: STRAIGHT TUBES | ||

|---|---|---|

| OD range | mm | Inch |

| min | 9.5 | 0.374 |

| max | 50.8 | 2.0 |

| WT range | mm | Inch |

| min | 0.89 | 0.035 |

| max | 4.5 | 0.177 |

Piping

Our nuclear pipes are manufactured for Class 1,2 & 3 piping for nuclear steam supply systems and non-nuclear island applications such as nuclear fuel reprocessing. We manufacture pipes with close dimensional tolerances, tight UT (Ultrasonic) control, controlled surface finishes and a high degree of cleanliness.

We work in close partnership with fabricators and designers.

We collaborate closely with fittings manufacturers to supply them with raw material for their fittings manufacture.

| PRODUCT: PIPING | ||

|---|---|---|

| OD range | mm | Inch |

| min | 6.0 | 0.236 |

| max | 280.0 | 11.024 |

| WT range | mm | Inch |

| min | 0.5 | 0.02 |

| max | 50.0 | 1.969 |

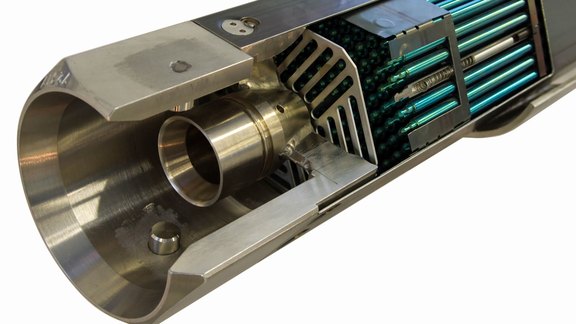

Feeder Pipes and Liner Tubes

Adding value by providing finished machined reactor core liner components in ferritic stainless combined with Ni alloy 690.

| REACTOR LINE COMPONENTS | ||

|---|---|---|

| OD range | mm | Inch |

| min | 1.60 | 0.063 |

| max | 244.5 | 9.63 |